Zhuoli BOPET: Designed for Thermal Transfer

2025-07-21

Zhuoli BOPET: Designed for Thermal Transfer

In thermal transfer ribbon (TTR) world, the base film directly impacts printing speed, image clarity, and operational consistency.

Many so-called “universal” BOPET films are not optimized for thermal transfer so you may ever experience:

❌ Ribbon breakage or edge curling

❌ Inconsistent print density and poor image quality

❌ Excessive friction during high-speed runs

❌ Shrinkage and deformation under elevated temperatures

✅ We found, and we take a different approach.

🌍 Leading the Shift Toward Smarter, Thinner Films

While 4.5μm BOPET remains a traditional industry standard, rising demands for efficiency and sustainability are driving the move toward thinner, higher-performance substrates.

Zhuoli is pioneering this transition — with films built from the ground up for thermal transfer applications.

🔍 Zhuoli’s Explore

🎯 1. Reduced Thickness, Enhanced Value

Film thickness reduced to 3.0μm, surpassing traditional norms. It enables longer ribbon roll lengths, lower raw material consumption, and reduced unit cost.

Among the first globally to apply thiner BOPET film in wax-based ribbons.

🛡️ 2. High Mechanical Strength and Dimensional Stability

Tensile strength up to 200 MPa, supporting high-speed printing without film failure.

Thermal shrinkage maintained below 1.5%, ensuring dimensional integrity during coating, slitting, and printing operations.

🌡️ 3. Thermally Resilient Across Operating Conditions

Stable performance under both elevated and low temperatures, minimizing seasonal performance variations.

Eliminates risks of warping, brittleness, or performance degradation during extended operation.

🧪 4. Engineered Surface Chemistry for Process Compatibility

Surface tension consistently maintained above 52 dyn/cm for superior coating adhesion.

Coating and release layers are precisely tuned to enhance compatibility with thermal print heads and ink systems.

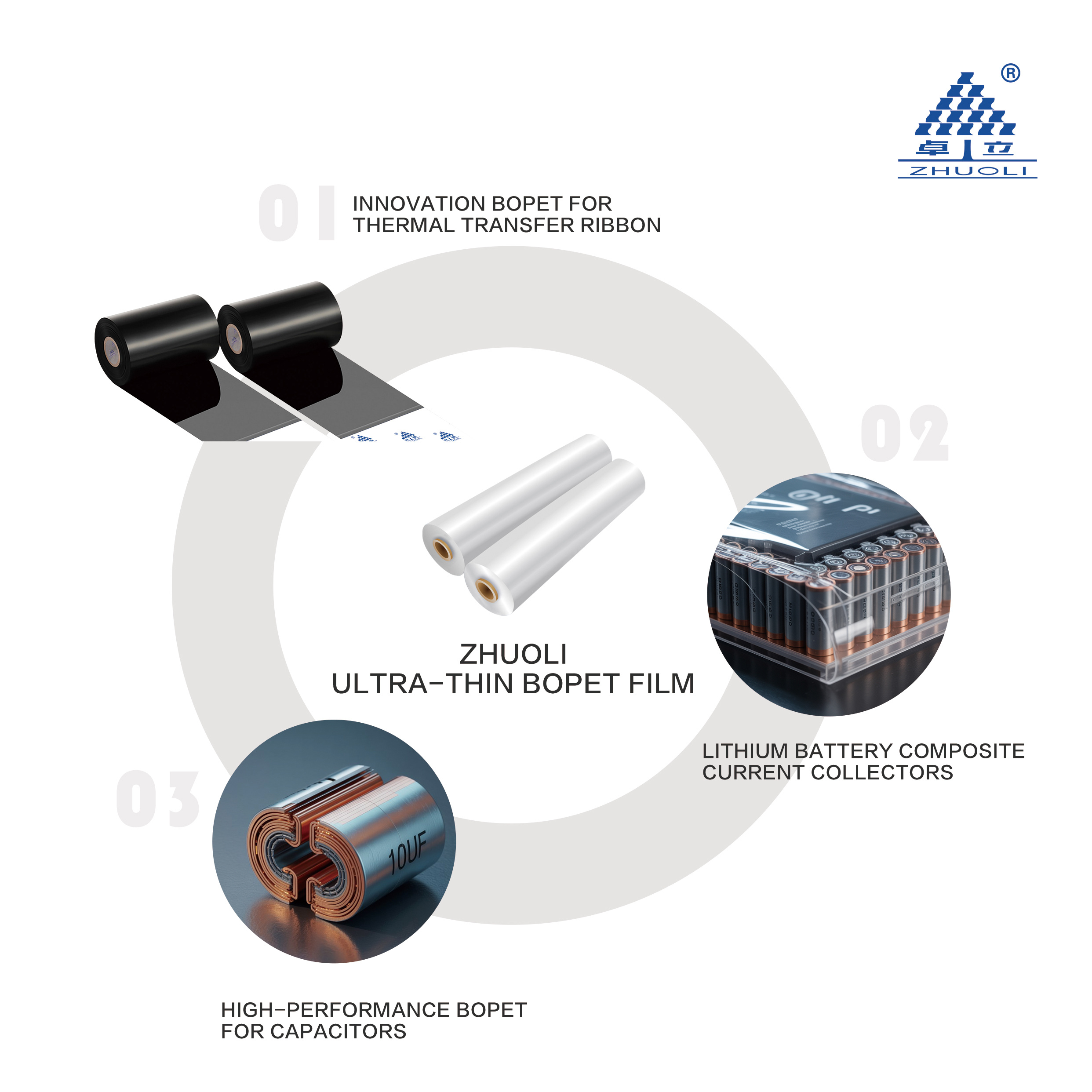

🌐 5. Broader Applicability Across Advanced Materials Fields

In addition to TTR, Zhuoli BOPET are suitable for lithium battery current collector structures, capacitor dielectric films, and other demanding electronic applications.

The product line meets industrial-grade performance standards and is compatible with large-scale processing and global supply requirements.

🚀 From Internal Use to Global Supply

Zhuoli’s BOPET film — proven in our own ribbon production — is now open to the global market.

We invite industry partners to access a film engineered with precision, built for performance, and ready to support the next generation of thermal transfer technology.

📩 Contact our team to learn more or request a technical sample:

Whatsapp: +44 7789278005

Email: market@jzzl.com

Previous Page:

Real-time information

Zhuoli BOPET: Designed for Thermal Transfer

2025-07-21

2024-05-23